It might be impossible to name the greatest racing engine of all time, but the Cosworth DFV certainly makes a case for itself. Introduced in 1967 bolted to the monocoque of a Lotus 49, the DFV, a 3.0-liter V-8, racked up 155 Formula 1 victories over a period of 16 years, and powered 12 driver's titles and 10 constructor's titles. Turbocharged, it dominated IndyCar, with 10 Indy 500 victories in a row. It even won Le Mans in 1975 and 1980. No other race engine has quite an illustrious resume.

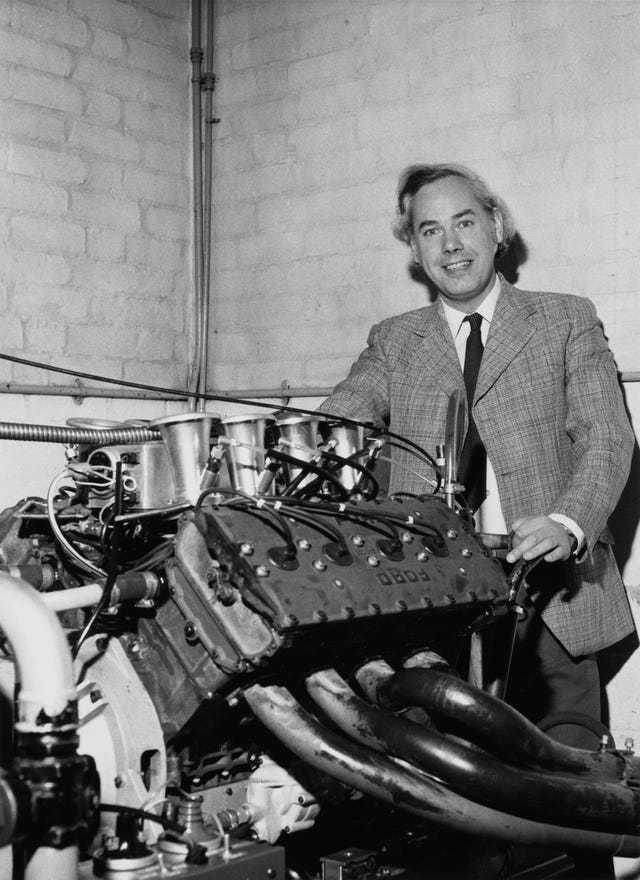

To understand why, we must talk about its designer, Keith Duckworth. After graduating with an engineering degree, Duckworth took a job with Lotus that lasted all of eight months because he didn't get along with founder Colin Chapman. Per Graham Robson's Grand Prix Ford, Duckworth yelled at Chapman for two-and-a-half hours upon quitting, then went and started Cosworth. Duckworth intended to run the business with good friend and colleague Mike Costin, but Costin was contracted to spend a few more years at Lotus.

Despite the blowout, Duckworth and Chapman retained a good working relationship. One of Keith Duckworth's first jobs at Cosworth was helping make the Ford-Lotus twin-cam four-cylinder reliable for the new Lotus Elan sports car and the Ford-Lotus Cortina sedan. Duckworth's work on both the twin-cam and racing versions of Ford's overhead-valve 997-cc Kent engine brought Cosworth to the attention of Walter Hayes, Ford UK's PR man and de facto motorsports boss.

This was Ford's "Total Performance" era, when the automaker put significant resources into motorsport, to pump up the image of its road cars. Throughout the Sixties, Ford had presence in endurance racing, rally, NASCAR, IndyCar, touring cars, and beginning in 1967, F1. Cosworth's Ford connection strengthened with its first full engine. The 1.0-liter SCA—Single Camshaft, type A— took advantage of Formula 2 regulations that stipulated a production block must be used. Duckworth naturally chose the Ford Kent block he was so familiar with, and Hayes got his company to pay Cosworth £17,500 for its development. Branded Ford on the valve covers, the SCA soon became the F2 engine of choice, winning championships in 1964 and 1965.

While many Lotus Sevens and junior formula cars were powered by Cosworth engines, in Formula 1, the company used Coventry Climax engines, like most British competitors. In 1963, the FIA announced a rule change that would see the 1.5-liter limit in F1 bumped to 3.0-liters, and two years later, Coventry Climax announced that it wouldn't build a new engine to this formula. This put Lotus in a bind.

Chapman knew Duckworth was the guy to build an engine, despite Cosworth never building a Grand Prix engine before. Lotus couldn't afford the project on its own, so in stepped Walter Hayes, who provided £100,000 of Ford's money to build the engine, in exchange for branding rights. With hindsight, a bargain considering the millions spent on the GT40 program. Around the same time, Duckworth was laying the groundwork for a new F2 engine, as a 1.6-liter formula was to be introduced in 1967. It would be based around the Ford Kent block, but it would sport a new four-valve head, giving it the name FVA, Four-Valve, type A.

The prevailing thinking of Formula 1 engine designers was that to increase power, you must increase cylinder count. There is truth to this. For an engine of a given displacement, the best way of making more power is to increase engine speeds, and a great way of increasing engine speeds is by making all the rotating components—crank, rods, pistons, valves, camshafts, etc.—lighter, reducing inertia. In theory, having more cylinders means each individual component is lighter, allowing for higher revs. Ferrari, Maserati, and Honda all made V-12s for the 3.0-liter formula, while BRM brought out an H-16, essentially two flat-eights stacked on top of each other (Lotus would use this engine as a stop-gap in 1966.) Duckworth thought differently. In his official biography he's quoted as saying "I decided that it was always better to work things out from first principles. One of my most important sayings, as a result, is that ‘it is better to be uninformed than ill-informed.’ After all, if you are uninformed your only option is to sit down and think about a solution. If you think hard enough, it is conceivable that you might get to the right answer.'' (First Principles, incidentally, is the title of the book.)

Yes, a greater cylinder count could lead to more horsepower, but you have to think of the car as a complete package. A V-8 would be smaller, lighter, and simpler. According to this magazine's technical analysis of the engine from July 1967, the smaller package would allow for a larger fuel tank. The DFV—Double Four-Valve—was also designed to be a stressed member of the chassis, doing away with the typical rear subframe for suspension.

"Keith was very straightforward," remembers Richard Langford, who worked at Cosworth in the Seventies and now builds racing engines as Langford Performance Engineering. "[He was] a stickler for having it right and pursuing all avenues in design. He was very good at problem solving."

These days, we're used to modularity in engine design, where inline-three, -four, and -six cylinders can be made up of the same basic components, and where a V-8 can (virtually) be born from two four-cylinders. Duckworth was long unconvinced that a DFV could be made up of two FVA, but he eventually came around. Even still, there are many differences. The block is obviously bespoke, and unlike the cast-iron unit in the FVA, the DFV's was made from aluminum. A bore of 85.7 mm is shared between the two, but the DFV's stroke is slightly shorter at 64.8 mm. This is the classic "oversquare" bore-stroke ratio common in race engines and high-performance road-car engines, allowing for higher revs. The 40-degree angle between the valves on the FVA was shortened to 32 degrees for the DFV to improve combustion and as it made the cylinder head slightly narrower.

The 90-degree angle between cylinder banks is typical of a V-8, and in racing, so too is the DFV's use of a flat-plane crankshaft. Duckworth went flat-plane to simplify the exhaust system—compare the "bundle-of-snakes'' headers on a GT40 V-8 to the simple setup on the DFV—and because a flat-plane crankshaft is lighter than the sort of cross-plane crank used in most road-going V-8s. Overall, the engine in its original form was 21.4 inches long, 27 inches wide, and 370 pounds in total. The valvetrain was safe up to 11,500 rpm, but redline was set at 9000 rpm, at which the DFV made its 400-hp power peak. Torque was 270 lb-ft at 7000 rpm, as we noted in our January 1967 issue. (For reference, Ferrari's V-12 of 1967 made 390 hp at 10,000 rpm.)

"The layout, the V-angle approach, having the cold air on the inside of the engine and the hot exhaust gasses coming out the side lead to better packaging," says Matthew Grant, founder of Cosworth-parts-supplier Modatek and a former engineer at Cosworth. "You could put pumps down the side…and if you look even up to today, the layout on a modern F1 engine is almost the same."

Remarkably, Duckworth finished the FVA and DFV in a nine-month period where he left the company operations to Mike Costin. He lost 40 pounds in the endeavor, but the result was worth it. On first testing the DFV, Graham Hill remarked "Well, it's got some poke. Not a bad old tool." At its debut in Zandvoort, Hill started from pole, but his engine suffered a broken camshaft timing gear. Jim Clark, however, streaked away, giving the 49 and the DFV victory on debut. Mike Hall, one of Duckworth's right-hand men is quoted in Grand Prix Ford as saying, "Keith never had any doubt that the new Formula One engine would work, first time, and give the predicted power. In our wildest dreams, we even hoped that it was going to win straight away, but I don’t think anyone really expected it to win, in Holland, on its first race."

Lotus didn't win the championship that year, that honor going to Denny Hulme and Brabham, but it was obvious that the DFV was the class of the field. For 1968, Hayes somehow convinced Lotus to give up exclusivity for the V-8, and soon the grid was filled with DFVs. Cosworth and Ford charged £7500 per DFV, and stipulated that the engine must be maintained by the factory, so no one could figure out its secrets. "That meant that people like Williams and Tyrell could buy an engine from Cosworth and stick it in their car and be successful," says Grant.

Still, that problem with Hill's engine at Zandvoort in '67 was indicative of larger problems. The torsional vibrations of the flat-plane V-8 caused cam-drive gears to break, and per First Principles, Clark's victory at the Dutch Grand Prix was down to luck as much as the Scotsman's famous mechanical sympathy. It was an issue that persisted with the DFV, and in some instances, the vibrations were so bad, camshafts would shatter. The solution was ingenious, a hub with quill shafts that dampened the vibrations wreaking havoc on the drive gears. This solved all the issues, and allowed for an even higher rev limit. "If it hadn't been solved, the engine would undoubtedly not have been developed as it went on to be," says Langford.

Formula 1 probably wouldn't have survived the fuel crises of the Seventies and sustained huge grids were it not for the availability and affordability of the DFV. By the mid-Seventies, a vast majority of the grid was DFV powered, with only the likes of Ferrari, Matra, and Alfa Romeo providing 12-cylinder alternatives. All the while, Duckworth and the team at Cosworth continued to refine the engine, improving reliability and power.

Duckworth was something of a purist, and wasn't a fan of turbocharging. It wouldn't be until 1977 that Renault would introduce a turbocharged engine to F1, but turbos were de rigueur in IndyCar by the late-Sixties. Most used turbocharged Offenhauser engines, the basic four-cylinder a pre-War design, but in 1972, Roger Penske sought to turbocharge the DFV without Cosworth's help to break up the Offy monopoly. The Vel's Parnelli Jones team then took up the mantle in 1974, and at this point, Duckworth decided that Cosworth should work on a turbo DFV of its own, the DFX. "We only went into Indy racing,” Duckworth said in Grand Prix Ford, “because I thought that our F1 business might be dying. So we produced the DFX. Then, instead of dying, our F1 business stood up well, the DFX engine took off like a rocket, and that caused us to expand rapidly once again."

In its earliest iterations, DFXs regularly produced 840 hp at 12,000 RPM, before USAC regulators wound boost pressure back. Langford says that because the DFV was designed to be a stressed member of a chassis, it could handle huge horsepower, far more than Duckworth ever imagined at the outset. Well into the late-Eighties, even after the DFV's fortunes fell in F1, the DFX was the engine to have for American open-wheel racing. Duckworth was less enthused about the prospects of using the DFV for sports car racing, apparently saying "If they’d asked me for an endurance engine, I’d have designed a f***ing endurance engine." It wasn't a particularly great sports-car engine, though it did just manage to survive the 1975 24 Hours of Le Mans in the Gulf-Mirage MR8 despite nearly shaking the car apart. A DFV-powered car from privateer Rondeau managed to win in 1980, giving the engine its last Le Mans victory.

Meanwhile in F1, the DFV stayed relevant thanks to ground-effect aerodynamics, which relied on venturis on either side of the engine to accelerate air underneath, creating low pressure, and thus, downforce. DFV-powered cars had an inherent advantage over the flat-12 Ferrari and Alfa Romeos, which were too long and wide for venturis. It wasn't until Renault made its turbocharged V-6 reliable and other OEMs like BMW and Honda joined F1 that the DFV started to fade. Its replacement, the turbocharged V-6 GBA arrived in 1986, though Cosworth never managed to replicate the DFV's success.

Matthew Grant didn't work with Duckworth directly, but many of his former colleagues at Cosworth did, the company's culture inextricably linked with the founder. "I think everyone admired Keith and respected him," Grant says. "Although he had a bit of a reputation for calling things as he saw them, and he certainly didn't tolerate fools gladly, they realized he only wanted to make the engine better."

Duckworth and Cosworth took that "return to first principles" approach to every element of an engine, be it a DFV, or the many other successful engines the company birthed. "If you had something break," Grant says, "you didn't just make it stronger, you understood why it broke in the first place, and sometimes, you might actually find that making the part lighter would make it stronger."

These days, the DFV remains popular thanks to the rise of historic grand prix racing in Europe, though series regulations limit the V-8 to 10,000 RPM, so no one is tempted to spend all sorts of money developing it even further. Now, the main focus is on reliability. "Its fundamentals are the same, but some of the materials now used to increase longevity of parts has changed," Langford says. "Better piston design, better piston rings, better cylinder-liner coatings… In its day, it was 500 miles between rebuilds, but nowadays you're probably doing 1500 miles. People might even stretch it further than that."

All the development wouldn't have mattered much if the fundamentals of the DFV weren't so good. Langford even remarks that some of its components, like much of the gear train, haven't changed since 1967. It's still hard to name the greatest racing engine ever, there's just so many classics, but the DFV makes a compelling case for itself.

A car enthusiast since childhood, Chris Perkins is Road & Track's engineering nerd and Porsche apologist. He joined the staff in 2016 and no one has figured out a way to fire him since. He street-parks a Porsche Boxster in Brooklyn, New York, much to the horror of everyone who sees the car, not least the author himself. He also insists he's not a convertible person, despite owning three.